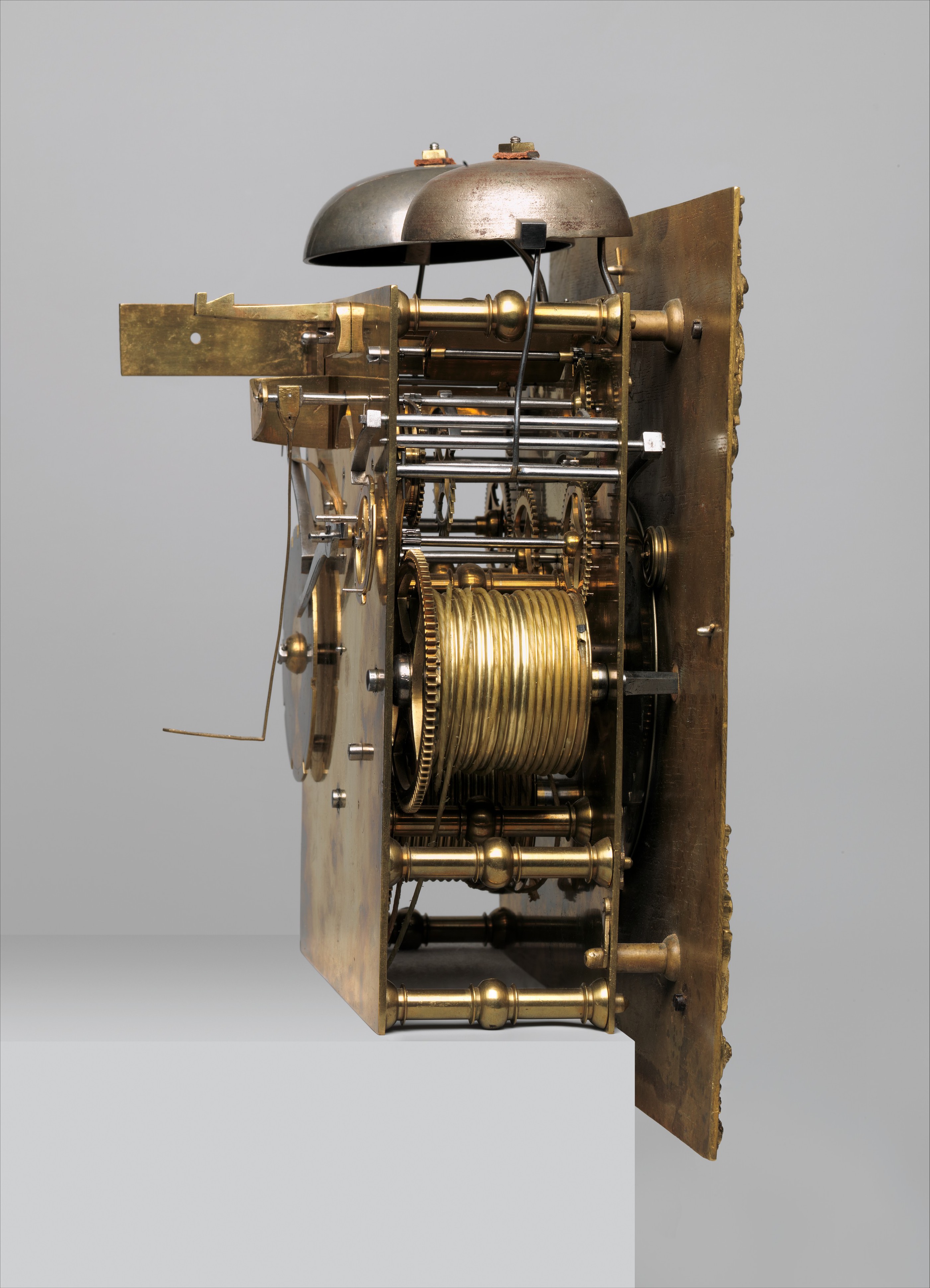

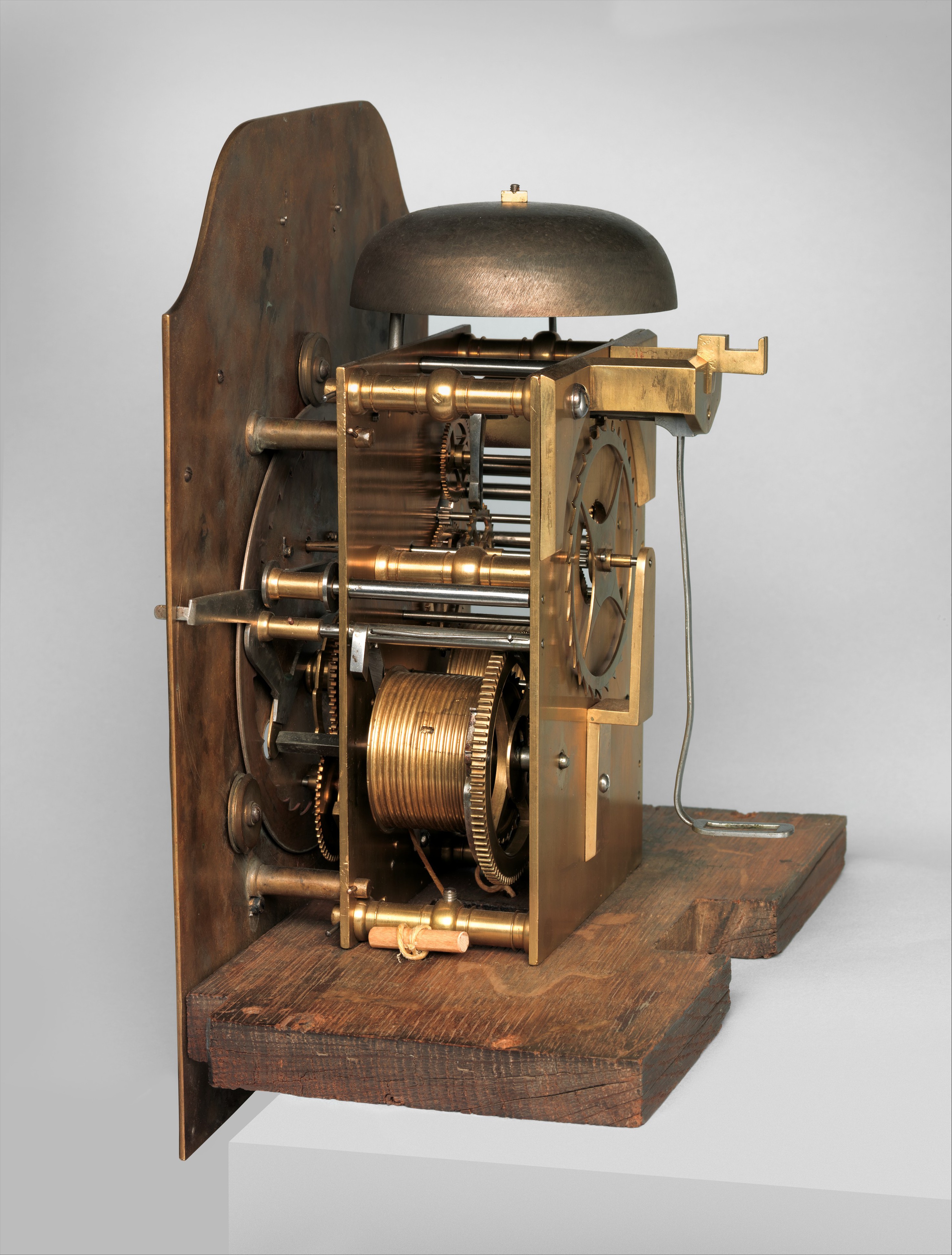

Expensive clocks of the past incorporated many such functions, and were probably some of the most complicated and mechanically sophisticated devices manufactured at the time. These automata take different forms, like doors opening on the clock, figures popping out and marching by, birds singing, and so on. Many of the clocks include complicated and ornate functions-or “automata”-which add an element of entertainment to the otherwise mundane time keepers. Now, it should be noted that Ray didn’t just repair and restore the timekeeping function of these clocks. Each unique part dictates its own method of repair or restoration. However, there are still some processes which are done almost exactly as they would have been three to five-hundred years ago, when the clocks were still “new.” This includes things like engraving and plating portions of a clock face, restoring numbers or markings, or hand filing small parts to fit.

Ray is not hesitant to adapt modern methods where the results justify them. However, this is one area where modern equipment does the job more accurately, with less chance of error, and without compromising the integrity of the finished part. This machine is the brainchild of the self-styled “crackpot inventor” Bryan Mumford, and is manufactured by Sherline Products. Many of Ray’s processes are done using traditional tools and/or methods in order to achieve the authentic look. Then, each time he hits the “Next” button, the table indexes the gear blank to the next position so that a new tooth can be cut. Ray simply enters the number of divisions (teeth) needed on the electronic keypad. It eliminates the traditional indexing plate, with all its holes and indexing finger, and replaces that with a stepper motor driven rotary table. The pair would use that machine to make clock gears, or “wheels,” as clock makers traditionally call them. Ray is aided in the wheel making by a piece of equipment that clock makers of the past would have probably given an arm and leg for-a CNC (computer numeric control) indexer.īeing able to use CNC simplifies the gear making process significantly.

Ray has also modified a Hardinge horizontal milling machine, and fitted it with the vertical head from a Bridgeport mill. For intermediate work, they have a Sherline lathe. These lathes include a Boley lathe, a Boley & Leinen lathe, a Derbyshire Model “A” Instrument lathe, and a South Bend 10″ “heavy” lathe for larger parts. The shops contain some traditional small watch and clock makers’ lathes, along with more contemporary equipment. Both shops are well equipped, and have extensive libraries. When it comes to work, Ray and his son have separate shops (which makes for good father/son relations). He remained in Newfane, and worked in what was once an old mill.Ī Combination of Modern and Traditional Tools After eventually growing tired of city life, in 1964 Ray moved his family and business to a more rural setting in Newfane, Vermont. (Waltham is sometimes called “watch city” because historically it has been home to several well-known timepiece manufacturers). In 1957, he immigrated to the United States and started a business repairing clocks near Boston, in Waltham, MA.

In 1952, Ray achieved Master status after building his own clock completely from scratch.Īfter two years in the RAF as an instrument specialist and photo analyst, Ray started his own business in London. These pursuits culminated with Ray’s graduation as a Craft Member of the British Horological Institute of London (CMBHI, now usually shortened to MBHI). Ray’s training there took place concurrently with his studies in mechanical engineering at the University of Edinburgh, Scotland. He would ultimately get the position, and wound up serving a 5-year apprenticeship with the R.L. The teacher learned that the shop had an opening for an apprentice, so Ray went along for the interview. When Ray was 16, he had a science teacher in high school who collected watches and dealt with a watch repair shop in Edinburgh. Ray Bates is a traditionally trained clockmaker who brought his craft and training from Great Britain to the United States.

From a Teenage Interest to a Lifetime of Horological Craftsmanship

0 kommentar(er)

0 kommentar(er)